Foreword:Looking forward to 2024, inflation in the United States has declined on the road of interest rate hikes lasting more than a year, but there is still a certain distance from the 2% inflation target. Observing the fundamentals of copper, the mine end is generally loose in 2023, and the transmission to the first half of 2024 is also the case, but with the global crude production capacity concentrated after 2024, the mine end will become increasingly tense until 2026, and the long-term trading logic shows that the supply side will support the copper price. In the electrolytic copper industry, the domestic electrolytic copper supply port will maintain a rapid growth rate in 2024, and the amount of copper metal will turn to excess, and the excess range is even more severe from the global perspective. Looking forward to the consumption port, the real estate completion end or will fall, then the real estate chain related industries will face greater pressure, will bring certain damage to domestic copper consumption; Domestic copper processing and deep processing exports are facing pressure, and under the expectation of overseas hidden inventory inflow growth, the domestic low inventory state will be significantly alleviated. It is expected that in 2024, Shanghai copper may be difficult to have a long-term backwardation market in 2022 and 2023, and contango may become the main trading logic.

In this context, the "2024 SMM (19th) Copper Industry Conference and Copper Industry Expo" will be held in Hangzhou, Zhejiang Province on April 22-24, 2024, with the theme of "Opportunities and Challenges for low-carbon, renewable and circular Development". At that time, Suzhou Xinsi Gas Technology Co., Ltd. will attend the conference, aiming to promote communication and cooperation between the parties, promote the healthy and stable development of the metal industry, and jointly discuss the development prospects of the supply and demand of the copper industry in 2024.

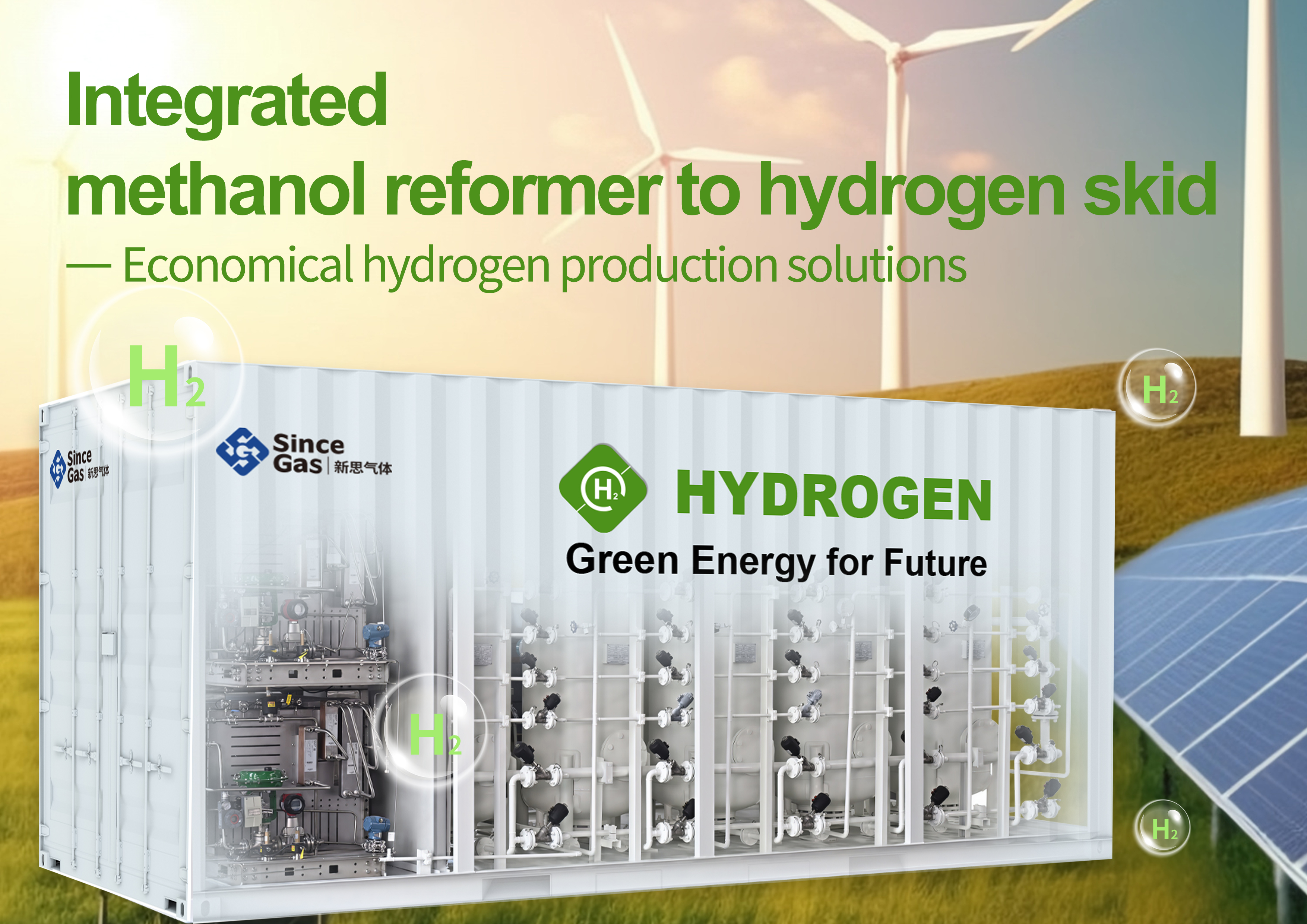

In the production and processing of some non-ferrous metals such as copper, tungsten, molybdenum, titanium, etc., hydrogen is mostly used as a reducing gas and a protective gas. In the annealing process of copper strip, copper pipe and copper wire, high purity hydrogen is needed as a protective gas to prevent surface oxidation and improve surface brightness. The energy-saving with low temperature and medium pressure ammonia carcker to hydrogen and integrated methanol reformer to hydrogen skid developed by Suzhou Since Gas can meet the demand for hydrogen in bright annealing scenarios.

In the bright annealing process of copper processing industry, a large amount of hydrogen is used, and most of this hydrogen is directly discharged into the atmosphere after bright annealing protection, resulting in huge waste and environmental pollution. Suzhou Sinsi Gas independently developed hydrogen recovery system, and has obtained the national invention patent (patent number: 2018100947048). The waste hydrogen/waste gas discharged by the annealing furnace enters the hydrogen recovery unit, is first cooled, washed and dedusted, and most of the water in the exhaust gas is condensed and then enters the Roots fan for pressurization. The waste hydrogen after pressure treatment by the fan enters the hydrogen purification unit or PSA for secondary treatment, so that the oxygen content and dew point of the gas are reduced to the production requirements. The purified hydrogen is re-used as raw hydrogen, and the recovery rate of waste hydrogen can reach more than 80%, which minimizes the cost of hydrogen for customers in the copper processing industry.

In the non-ferrous metal industry, especially in the production process of copper processing, the purity of nitrogen is very demanding. Suzhou Xinsi Gas has designed and developed a series of products for high-purity nitrogen in copper processing industry, including one-step production of high-purity nitrogen with air as raw material, two-step of high-purity nitrogen purifier with hydrogen, and two-step of high-purity nitrogen purifier without hydrogen, with high stability of nitrogen production and lower energy consumption, which greatly reduces the cost of nitrogen for customers.

For nearly 20 years, Suzhou Since Gas has provided gas generation solutions for 300+ customers in the copper processing industry, and has won unanimous praise from our customers.

All rights reserved © Copyright 2016 Suzhou Since Gas Technology Co., Ltd