The core principle of the ammonia decomposition hydrogen production system is to use liquid ammonia as the raw material and convert it into a hydrogen-nitrogen mixture gas through a series of precise processes. Liquid ammonia first enters the vaporizer, where it absorbs heat to vaporize and become gaseous ammonia. Then, the gaseous ammonia is heated to a high temperature and undergoes a miraculous fission reaction under the action of a nickel-based catalyst, decomposing into a mixture gas containing 75% hydrogen and 25% nitrogen.

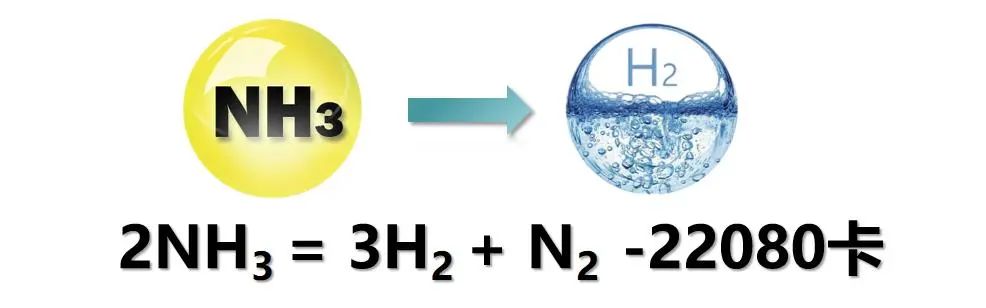

The chemical reaction equation is: 2NH₃ = N₂ + 3H₂ - 22080 calories. This means that under standard conditions, 1 kg of liquid ammonia can completely decompose to produce 2.64 Nm³ of hydrogen-nitrogen mixture gas. The decomposed mixture gas is then cooled by heat exchange and enters the dryer for deep treatment. The residual ammonia and trace amounts of water are adsorbed and dried, and finally, pure hydrogen-nitrogen mixture gas is obtained. If higher purity of hydrogen is required, a PSA purification device can be used in conjunction to further produce pure hydrogen with a purity of up to 99.999%.

On the eve of the hydrogen energy industry's boom, the ammonia decomposition system, with its triple advantages of "economy, safety and sustainability", has become an "inevitable choice" for industrial transformation. Whether it is the practical need for cost reduction and efficiency improvement, or the strategic layout to seize the carbon neutrality race, this technology will open up new growth spaces for enterprises. If you want to know the detailed information of the above products or are interested in our products, please visit the website of Since Gas: www.sincegas.com for consultation.

All rights reserved © Copyright 2016 Suzhou Since Gas Technology Co., Ltd